More Information

Submitted: July 18, 2022 | Approved: July 27, 2022 | Published: July 28, 2022

How to cite this article: Tingdong X. A reaction and movement of vacancy and solute atom in metals under elastic tensile stress. Ann Adv Chem. 2022; 6: 021-022.

DOI: 10.29328/journal.aac.1001027

Copyright License: © 2022 Tingdong X. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

A reaction and movement of vacancy and solute atom in metals under elastic tensile stress

Xu Tingdong*

Central Iron & Steel Research Institute, Beijing 100081, China

*Address for Correspondence: Xu Tingdong, Central Iron & Steel Research Institute, Beijing 100081, China, Email: [email protected]

In the 17th century, Robert Hooke, an English physicist, proposed Hooke’s law. Since then, the theory of elastic deformation in metals has been restricted to a macroscopic frame that is normalized by Hooke’s law. From the start of the 21st century, Xu has established a microscopic theory of elastic deformation based on Hooke’s law to describe the reaction and movement of vacancy and solute atom in metals under elastic tensile stress [1,2].

In this microscopic theory [1,2], vacancies in the matrix can be absorbed into grain boundaries and dislocation regions which work as a trap of vacancies under elastic tension stress at a temperature. Moreover, the migrating vacancies may drag solute atoms in the form of vacancy-solute atom complexes towards the grain boundaries and dislocations, to create an excess concentration of solutes there. At the same time, a concomitant but reverse diffusion of solute atoms away from the boundaries and the dislocation takes place along the established solute concentration gradient. Accordingly, an elastic stress aging time or an Elastic Deformation Time (EDT) must exist at which the backward solute diffusion balances the forward complex diffusion, and the solute concentrations at the grain boundary and dislocation reach a maximum value. This EDT is called the critical time of elastic deformation at the temperature T expressed as tc(T). In the case of grain boundary, tc(T) is given by

(1)

where Di(T) and Dc(T) are the diffusion coefficients for solute atoms and complexes in the matrix, respectively, and both are affected by the elastic deformation; r is the grain radius; and δ is a numerical constant, given by δ = 6K2, where K = r/L, L is the diffusion length of solute during the critical time at temperature T. In the case of dislocation, tc(T), is given by

(2)

The maximum concentration of solute under stress equilibrium in the grain boundary and dislocation regions Cb(σ=σ) is formulated as equation (3).

(3)

where Cb(σ=0) is the equilibrium concentration of solute atoms at grain boundaries and dislocations at a temperature in the absence of stress, σ is the tensile stress, Egb is the elastic or Young’s modulus at grain boundary or dislocation, Fv is the formation energy of a vacancy in the boundary and dislocation region and K0 is a geometric constant.

Based on Equations (1), (2), and (3), the kinetic equations are formulated to describe the solute concentration Cb(t) varying with the EDT at the grain boundary or dislocation at a temperature. For the segregation phase, i.e., when the EDT is shorter than the critical time, the kinetic equation is

(4)

For the desegregation phase, i.e., when the EDT is longer than the critical time, the kinetic equation is

(5)

Where Cg is the concentration of solute within the grains, α = Cb(σ=σ)/Cg and d is the width of the concentrated layer at the grain boundary and dislocation [1,3].

The kinetic equations under the action of elastic tensile stress, (4) and (5), describe the variation of solute concentration at grain boundaries and dislocations with EDT, and the variation of metallic micro-structure with the time of tensile stress action. Hence equations (4) and (5) are state functions describing the variation of microstructure with EDT at the atomic level of metals [1,3].

The measurement uncertainty of tensile testing results influenced by test temperature and strain rate variations is a widespread characteristic of impurity-containing metals. The measurement uncertainty results, in general, in current testing results determined at a given temperature and strain rate deviating from the original properties of the specimens possessed before testing. Since the time of Galileo, the results of tensile testing have been incorrectly interpreted as the original mechanical properties of specimens, thereby forming a paradox in the system of tensile testing [3,4].

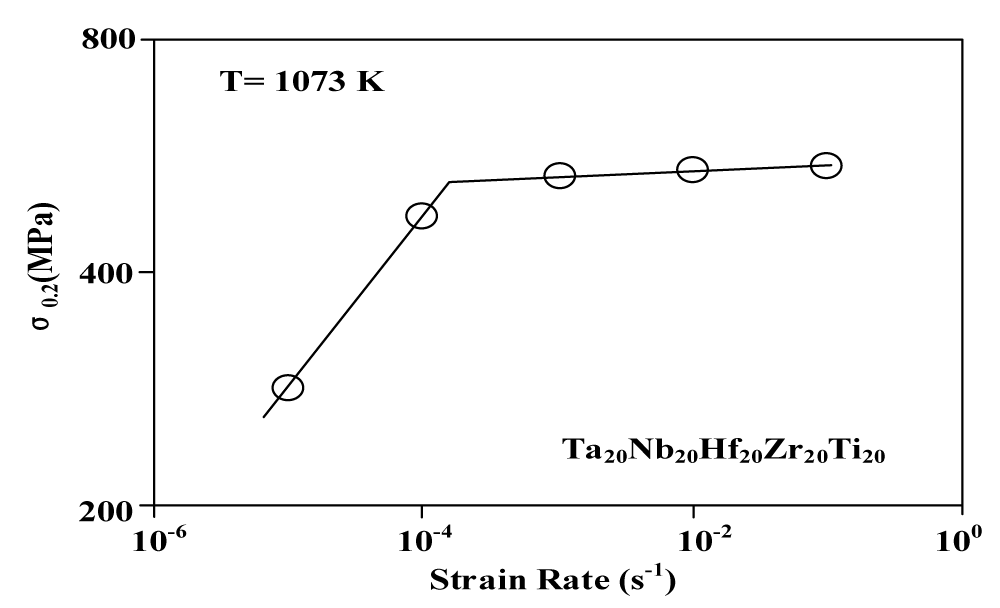

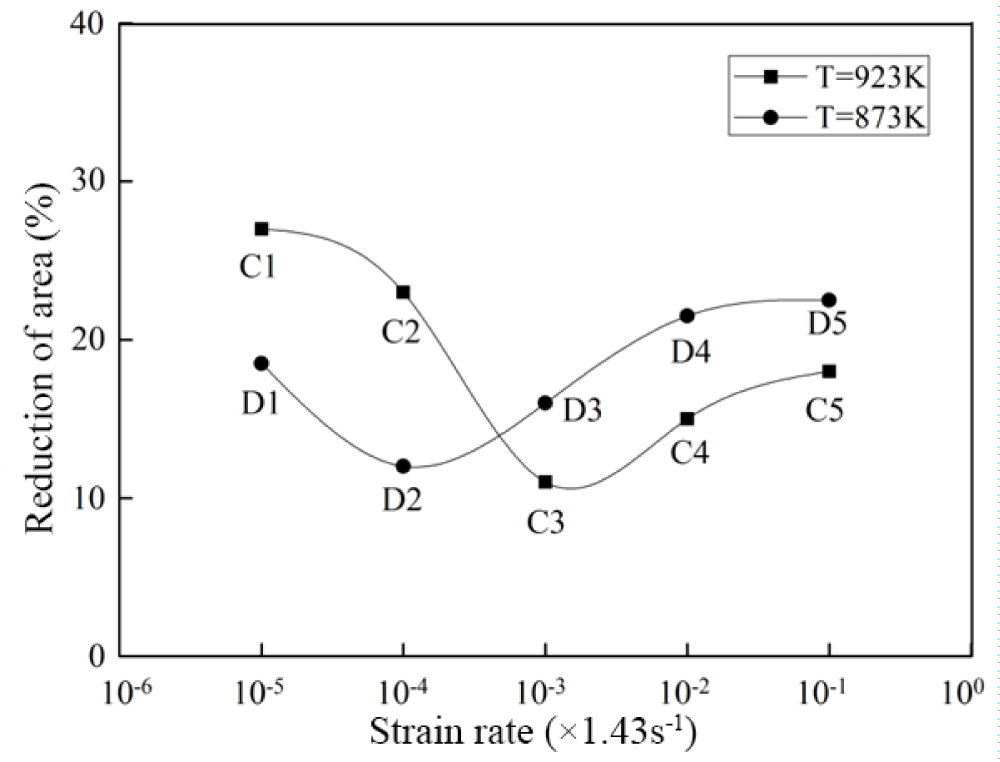

Based on the microscopic theory of elastic deformation, the equations (1), (2), (3), (4), and (5), the changes in micro-structure induced by elastic deformation have been described at the atomic level so that the concentration of impurity atom at grain boundaries and around dislocations varies with the EDT. Different testing temperatures and strain rates induce different EDT, leading to different impurity concentrations at grain boundaries and around dislocations, and therefore different mechanical properties. This is the mechanism for the measurement uncertainty of mechanical properties in metals. Hence a new technology system for tensile testing is proposed by using a curve of “mechanical property−tensile strain rate” at a given temperature, such as Figures 1,2 the “yield strength- -tensile strain rate”curve, and the “reduction of the area -- tensile strain rate” curve [3,4].

Figure 1: The “yield strength– tensile strain rate” curve of high-entropy TaNbHfZrTi alloy at 1073 K. Reprinted with permission from ref [4].

Figure 2: “Reduction of area -- tensile strain rate” curve for Fe-17Cr steel determined at 923 K (C) and 873 K (D). Reprinted with permission from ref [4].

The curves and equations (4) (5) establish a relationship of one-to-one correspondence between the micro-structure state and macro-mechanical property for the tested metals. Consequently, the mechanical properties of metals, including the original mechanical properties, the service mechanical properties, and the mechanical properties during processing deformation, these new concepts in metallic mechanics, can all be characterized through these curves, although these three kinds of mechanical properties are not identical to each other [4].

A method of measuring original mechanical properties is given in reference 4 that the faster the tensile strain rate is, the closer the property on the“mechanical property-tensile strain rate” curve is to the original mechanical property. There must be a strain rate that is fast enough to determine the original mechanical property of the tested metal on the curve. As shown in Figure 1, for high-entropy TaNbHfZrTi alloy at 1073 K that the yield strength increases from 285 to 535 MPa when the tensile strain rate increases from about 10-5s-1 to 10-3s-1, showing the measurement uncertainty of yield strength relative to the variation of strain rate. With further increasing strain rate from from 10-2s-1 to 10-1s-1 the yield strength maintains at about 543 to 550 MPa, implying that the strain rate from 10-2s-1 to 10-1 s-1 is high enough to obtain the original yield strength for the alloy, being about 550 MPa at 1073K [4].

In references 1 and 4, for the first time, a relationship of one-to-one correspondence between the microstructure and the macro-mechanical property is established in metals.

Funding

This work was supported by the National Natural Science Foundation of China (grant nos. 51871064 and 52071088).

- Tingdong X. Creating and destroying vacancies in solids and non-equilibrium grain-boundary segregation. Philosophical Magazine. 2003; 83 (7):889-899.

- Tingdong X. Grain-boundary anelastic relaxation and non-equilibrium dilution induced by compressive stress and its kinetic simulation. Philosophical Magazine. 2007; 87(10):1581-1599

- Tingdong X. Interfacial Segregation and Embrittlement. In: Saleem Hashmi (editor-in-chief). Reference Module in Materials Science and Materials Engineering. Oxford: Elsevier. 2016; 1-17. doi:10.1016/B978-0-12-803581-8.03232-X

- Tingdong X. Wang K. Song S. Measurement Uncertainty and Representation of Tensile Mechanical Properties in Metals. Metals. 2021; 11: 1733 https://doi.org/10.3390/met11111733